To service greater China market demand for high-quality stainless steel products, Walsin Yantai Stainless Steel Co. Ltd. has contracted with Primetals Technologies to design and manufacture a new stainless steel combination mill to convert billets from an existing plant into finished products with precision tolerance and surface quality. In-line-processing will lower production costs. Start-up is expected in late 2020.

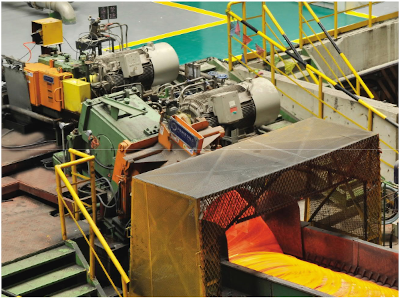

Located in Yantai, Shandong Province, China, the new mill project with Primetals Technologies will be completed in consortium with CERI Long Product Co. Ltd., including all electrics and automation to approach Industry 4.0. The combination mill will have a straight bar outlet, a bar-in-coil outlet, and a wire rod outlet. The mill train will feature new- generation Red Ring stands, feeding a cooling bed equipped with abrasive saws, slow bin cooling and bundle-forming stations. The bar-in-coil outlet will utilize the latest high-speed pouring reels with direct quenching. The rod outlet will include a Morgan No-Twist Mill, Morgan High Speed Shear, Morgan Rod Reducing/Sizing Mill and Morgan Stelmor Conveyor, as well as an in-line direct solution treatment line for lower production costs, with vertical pallet coil handling.

Primetals Technologies has supplied several copper mills to Walsin Yantai Stainless Steel parent company Walsin Lihwa Corporation in previous years. Walsin Lihwa Corporation, established in 1966, is not only the leading manufacturer of copper wires and rods, power cables, and specialty steel long product include seamless tube and piping, and brightening bar in the Greater China region but also a leading real estate developer across the Taiwan Strait. No-Twist, Red Ring and Stelmor are registered trademarks of Primetals Technologies Ltd in certain countries.