In August 2019, the hot strip mill of U.S. Steel Košice in Slovakia resumed operation after the successful modernization of the roughing mill main drive. SMS group supplied the spur gear unit.

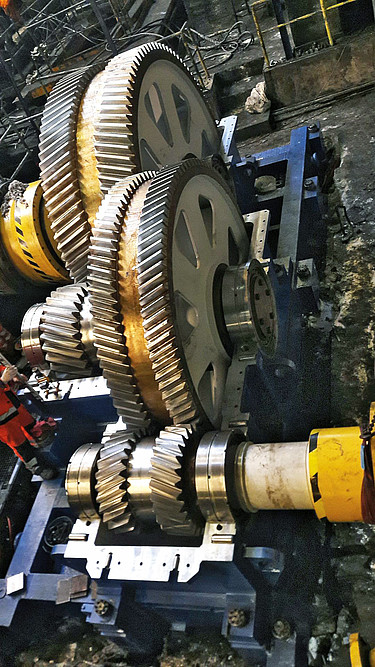

A roughing mill spur gear unit is an impressive component not only because of its size. It is one of the main drives of the roughing mill and thus transmits the highest torques that are necessary for transfer bar rolling. This makes it one of the components with special demands.

Advanced gear design for optimal load distribution

Essential components of the spur gear units are the gears. Gears from SMS group are executed in our “Advanced Gear Design”. The tooth and flank profiles are individually and precisely designed for the specific requirements, so that an optimal, even load distribution over the entire tooth flank is achieved during load conditions. This increases the safety and the torque capacity of the gears compared to the standard toothing design. The production competence of SMS group allows spur gears with very large diameters to be produced. As a result, the main gears of a roughing mill can be designed with less gear stages compared to the usual design of competitors. This results in savings in rolling operation, such as energy, media and installed components.

Modernization of roughing mill stand

In fall 2018, with these advantages in mind, U.S. Steel Košice (Slovakia) placed an order with SMS group to modernize the main gear unit of the second roughing mill stand of its hot strip mill. U.S. Steel Košice has been operating the plant since 1996. The scope of supply included a completely new, state-of-the-art two-stage gearbox including input and output couplings.

“Special customer requirements as well as the local conditions such as the existing foundation, were taken into account,” says Nikolai Penner from the Drive Systems Department of SMS group, who was responsible for the sales-related part of the project. Furthermore, the fast and smooth conversion was in the foreground. The components were manufactured and pre-assembled in the Hilchenbach workshop of SMS group.

After the pre-assembly, the gearbox with a total weight of 118 tons was delivered to U.S. Steel Košice. There, the gearbox could not be moved to its place of use in one piece due to the load limitation of the overhead crane. It had to be dismantled and assembled on site together with the customer. The partnership-based cooperation was very successful, so that production could be resumed in August 2019, as scheduled, after a planned shutdown of ten days.