Big River Steel (BRS) is the latest in technological exploitation in CSP® technology and started production in December 2016. The approach of BRS is to focus on highly flexible production of value added steel grades. Our expert on CSP® technology Karl Hoen describes the technology of the Big River Steel plant as well the impressive operational results in the first two years of production.

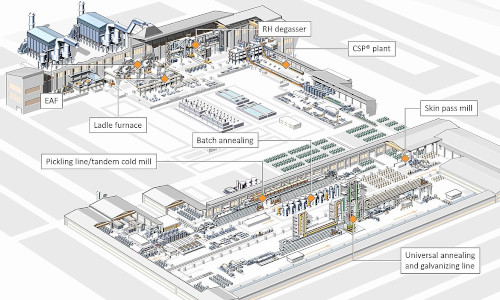

Plant overview

The plant complex of Big River Steel is located in Osceola, Arkansas, USA on the banks of the Mississippi River, well positioned to the fastest growing steel consuming region in the United States. Consequently, BRS identified profitable market segments such as HSLA, API Linepipe, OCTG grades for energy sector, extra deep drawing steels (EDDS) and AHSS steels for automotive sectors. Further CRML (cold rolled motor lamination) and NGO SP (non-grain oriented semi-processed) electrical grades are part of its product mix. In the future, BRS also intends to prepare itself for the production of CGO (conventional grain oriented silicon steel) and H-GO (high permeability grain oriented silicon steel).

In the first phase, the plant complex of BRS consists of a steelmaking plant, a single-strand CSP® plant with a capacity of 1.5 million t/ year, a PLTCM, a combined continuous annealing and hot dip galvanizing line, batch annealing furnaces and an offline skin pass mill.

STEEL MAKING AND ROLLING

The steel making plant consists of a direct current electrical arc furnace with a tapping weight of 150 t. Charge material includes commercial scrap grades and depending on the steel grade produced, pig iron, DRI or HBI. For metallurgical refining and alloying a ladle furnace is used designed as twin station with joint electrodes to reduce idle time due to ladle handling.

For vacuum treatment a Ruhrstahl-Heraeus (RH) degasser is installed with TOP lance for forced decarburization and chemical heating. The RH degasser has a capacity of 145 t per ladle. The process is characterized by short treatment time and flexible ladle handling. This gives BRS the opportunity of economical mass production of high quality steel grades with ultra-low carbon and low gas content. The coupling of EAF and RH degasser is the first one in North America.

The CSP® plant is designed to produce strips with a width of up to 1930 mm (76”) and a final thickness between 1.4 mm and 25.4 mm. In the first phase, the CSP® plant consist of a vertical solid bending (VSB) type CSP® caster, the CSP® furnace and the 6-stand CSP® mill with laminar cooling and downcoiler.

DOWNSTREAM EQUIPMENT

The pickling line tandem cold mill (PLTCM) is designed to process up to 900,000 tons of steel strip per year with strip widths ranging from 914 to 1,880 mm and an entry thickness in the range of 1.4 to 5.0 mm. It is equipped with an X-Pro® laser welder, a scale breaker, a turbulence pickling section and a five stand tandem cold mill. The latter reduces the steel strip to final gauges of 0.27 to 1.4 mm. To produce pickled and oiled strip the pickling line is equipped in the exit of the pickling section with the DUMA-BANDZINK oiling machine.

The continuous annealing and hot dip galvanizing line gives great flexibility in strip processing enabling the production of coated and uncoated strips for a wide range of steel grades. This is done highly energy efficient and environmental friendly due to the intelligent I-furnace technology integrating process models and innovative online measurement technologies.

In addition, BRS uses 25 batch annealing furnaces with innovative process intelligent ensuring excellent cold strip treatment and throughput optimized operation with an annual capacity of 413.000 t. The subsequent offline Skin Pass Mill with a rolling force of 18,000 kN enable skin passing of super hard complex phase automotive grades and is capable of providing up to 13 % elongation for motor lamination grades.