Danieli completed a successful modernization of the spooler line for Bar Mill #2 at Alfa Acciai, Brescia, Italy, implementing for the first-time simultaneous coiling of small-diameter rods by two coilers as part of a single line. The upgrade allows the steelmaker to increase its production of coiled rod products, in line with current market demand, and also results in a significant improvement to the characteristics and mechanical properties of the finished coils.

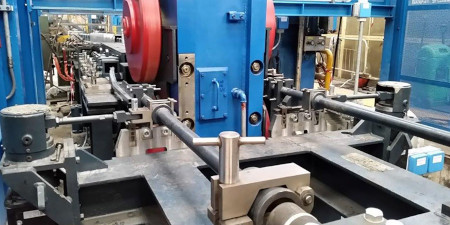

The project involved a complete renewal of the mill automation system as well as some new equipment to direct both strands of the split rolling mill to the two coilers.

Bar Mill #2 has been equipped with Danieli EWR® billet-welding capability since 2004, joining two billets to produce a spooled coil weighing about 3 tons. For small-diameter products produced by twin split rolling, four billets are needed to obtain two 3-ton coils.

Prior to this modernization, just one strand of the split rolling line fed the spooler line and the alternate strand delivered material to the cooling bed as straight bars.

Following the modernization, it is possible for both strands to feed two coilers, simultaneously.

As a result, Alfa Acciai will increase spooled bar output from 50% to 80% of hourly production and reduce straight bar output to 20% of the total.

This particular production practice was studied and developed jointly by Alfa Acciai and Danieli during the Covid19 pandemic lockdown, and concluded positively with on-time commissioning and successful start-up, and full mutual satisfaction, reconfirming the long partnership between the two Groups.