- Enables SUNSCO to build a stable position in the market with the growing demand for thinner building materials

- First application in Vietnam, with optimized roll forces for thinner building materials

- Enables to produce high quality materials as thin as 0.2 millimeters, and to reduce costs

- Employing smaller diameter work rolls to reduce rolling loads

- Mill concept to save investment and maintenance costs

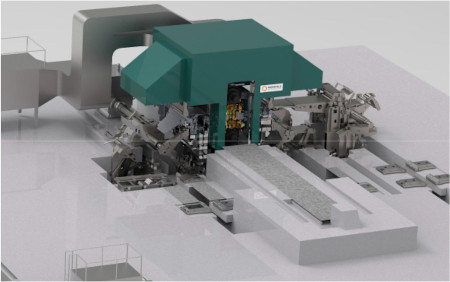

Vietnamese steel producer Maruichi Sun Steel Joint Stock Company (SUNSCO) is in a deal with Primetals Technologies to introduce light-duty Hyper Universal Crown-mill (Hyper UC-mill) at a SUNSCO production site in Binh Duong Province in Vietnam. This mill will be installed as its first application in Vietnam. It is a compact, light duty type of Hyper UC-mill, a RCM, employing smaller diameter work rolls, thus reducing rolling loads. It allows the production of thinner materials of high quality at fewer costs. Also, the mill concept saves investment and maintenance costs. The solution set up at SUNSCO will be the first case of Hyper UC-mill to expand the original mill concept to the production of thinner and soft material by using optimized roll forces. The new mill will enable SUNSCO to build a stable position in the market with the growing demand for thinner materials for the building and construction industries. Under the climatic conditions prevalent in Southeast Asian countries like Vietnam, thinner sheet-based roof materials need to be replaced regularly and are therefore in high demand. The challenge is to produce building materials durable and of high quality, but with continually reduced thickness to save costs.

SUNSCO was established in 1996 as the first 100% foreign capital invested steel company in Vietnam. The company produces and sells the following items: molten zinc, 55% Al-Zn galvanized steel coil, color coated steel coil, and steel pipe. SUNSCO ́s products are mainly used for civil and building construction, structural uses, furniture, bicycle and motorbike parts and other industrial uses. The company is part of the Maruichi Group, with Maruichi Steel Tube Ltd. holding 72.53% of the shares.

Primetals Technologies ́ scope of supply encompasses the complete mechanical and electrical equipment. Primetals Technologies will be responsible for the supervision of installation and commissioning as well. The light mill will process thin sheets with end-product thicknesses down to 0.2 millimeters and a width of 1,250 millimeters (4 feet). This particular mill can produce sheets as thin as 0.1 millimeters. It, along with No. 1 CRM previously delivered by Primetals Technologies, will increase its annual production capacity to total 250,000 tons.

Hyper UC-mill was developed by Primetals Technologies to achieve high performances of strip gauge and flatness control for High Strength Steel (HSS) rolling. This technology is also applicable for rolling high grades of non-grain oriented silicon steel and thinner products. The technology stands on an optimized roll diameter combination (small work, intermediate and back-up rolls,) a “work roll driven system” to achieve high flatness controllability, and the development of a high strength small diameter spindle to drive the work roll.

Hyper UC-mill is a registered trademark of Primetals Technologies in certain countries.