From rubber material to diamond layer coating: New and precise test method analyzes strength of surfaces and strength distribution within mono layers and multi layers

For the strength evaluation of surfaces methods such as pull/push strength, press-in strength, or friction/scratch tests have been used. However with these methods it is often not possible to test thin films because test data are not meaningful and layers or substrates beneath the tested layer can be damaged which can lead to invalid test results. For this reason the newly developed Micro-Slurry-Jet-Erosion (MSE) Test System was developed by the Japanese Company Palmeso Co. Ltd. after 10 years of research & development with Fukui University. It evaluates the surface strength using a micro particle slurry jet. This allows testing of very hard materials such as diamond layer coatings but also very soft materials such as rubber type coatings can be tested. The fact that the strength distribution within mono and multi-layer coatings can be optained makes a very precise analysis now possible. The MSE Test System is available through the European Distributor Rubröder International in Bendorf, Germany.

Thin Films are found today in any industry and often represent new developments not only in the electronics industry but also in aerospace as well as medical technology. Therefore the continuous optimization of thin film coatings as well as suitable test methods are of upmost importance. But also in optical coatings, composite materials, cutting tools, grinding tools as well as other tools and in sintered materials high quality standards of coatings are required. However the traditional material strength testing methods are often not suitable for thin film coatings and can damage layers and substrates beneath the tested coating. Therefore Palmeso, in cooperation with Fukui University, has developed a precision test method which can evaluate hard coatings as well as soft materials easily.

Strength measurement by micron metal oxide particle slurry jet

Instead of relying on pull/push strength, press-in strength, or friction/scratch methods, the MSE test system features a completely different method. It utilizes the micro particle jet erosion power as a new reference standard. The micro slurry jet ensures constant material erosion of the surface which allows to measure the strength distribution continuously by sub-micron resolution from surface to depth (down to ca. 300µm) regardless of substrate hardness.

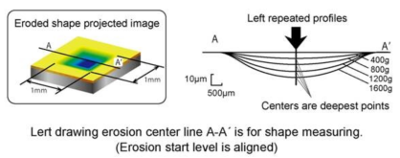

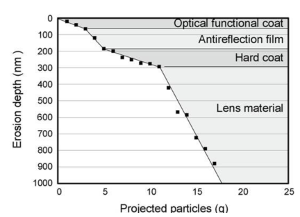

The test machine developed by Palmeso includes an erosion chamber and a profilometer which measures the erosion depth. The micro particle jet consists of a mixture of water and 1.2 µm metal oxide particles which is delivered to a nozzle inside the erosion chamber and injected onto the material surface using high pressure. In most cases the particle material is angular aluminum oxide and in some cases it is silica. The slurry beam is injected onto the specimen surface at a velocity of 100m/s and a throughput of several billion particles per second and erodes the surface constantly in nanometer range without damaging layers or substrate beneath the layer being tested. Therefore it can be described as “mechanical property analysis”. The erosion depth will then be measured at a resolution of 10-20nm and plotted against the amount of particles in g. Since the jet velocity can be adjusted to each material characteristic – a throughput of 1 to 1.000 g/cycle is possible –, the substrate will not be effected at all.

Regardless of the number of layers being positioned on top of each other MSE measures each individual layer at a resolution of 10 – 20 nm as long as the layer is at least 100nm thin and not thicker than 300µm. Theoretically besides extremely thin coatings which cannot be tested with any other method, also multi-layer systems can now be analyzed.

Evaluation of strength distribution from surface to depth is now possible

The optained data is processed by a special proprietary software developed by Palmeso. A database of reference materials is also provided by Palmeso. This allows detection of material defects as well as development of completely new coatings and surface treatments. While it is difficult or not possible to analyse thin films by traditional material strength measuring methods, the MSE test system allows to precisely measure the strength distribution from surface to 300 µm depth at a resolution of 10-20 nm. This allows optimization of coating processes of soft materials as well as Hard Thin Films such as DLC or TiN, TiC and WC to an extend which has not been possible before. Therefore MSE method is likely to become a standard test in R&D and quality control facilities.

The benefits of MSE testing are as follows:

- Determining suitable coating materials

- Determining production process (ex. appropriate temperature conditions, etc.) by checking the strength of coated films produced under different conditions

- Helps to investigate defects (fault reasons)

- To determine and compare deteriorated samples

- To measure thicknesses of each layer between surface and substrate

Additional information for readers/spectators/interested parties:

Theodor-Neizert-Straße 1, 56170 Bendorf (Germany)

Phone: + 49 2622 8979892, Fax: + 49 2631 4500050

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Website: www.rubroeder.systems