Additive manufacturing is experiencing a significant upswing in the steel industry. Ugitech, a Swiss Steel Group company, has dedicated itself to this trendy topic and, with UGIWAM®, offers special steel of different compositions for the wire-based additive manufacturing process. Whether austenitic, martensitic or ferritic, duplex wire or nickel-based wire, Ugitech enables perfect adaptation to different requirements and applications.

As a leading supplier of stainless steels and alloys for welding applications, Ugitech provides a wide range of stainless steel and nickel-based wires. The Swiss Steel Group company utilises its many years of experience in steel production to offer material of the highest quality for use in additive manufacturing processes. Findings from the company's own research and development centre flow into the production of the wires, which were developed primarily for Wire Arc Additive Manufacturing (WAAM).

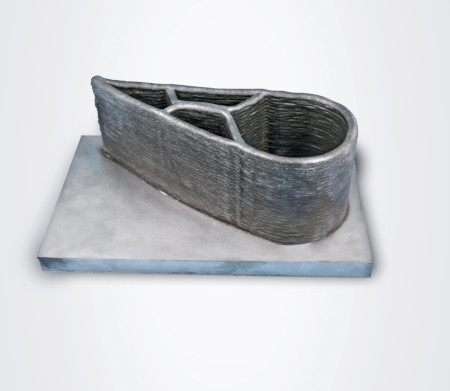

WAAM – special manufacturing technology for 3D components

The wire-based additive manufacturing process is becoming increasingly important in the steel industry (in addition to the powder bed system and powder feed system). In Wire Arc Additive Manufacturing, the externally supplied welding wire is melted by an electric arc. The desired 3D components are created layer by layer. The advantages of this manufacturing process are plain to see. Large components with length in meters can be produced in a cost-effective manner in a short period of time. At up to 5 kg/hour, WAAM technology achieves higher productivity than selective laser melting or electron beam melting. Individual component geometries are created that can only be produced with great effort and increased costs using conventional processes. The near net shape production enables the geometry to be quickly established with low material consumption and waste. As the procedure does not involve the use of lasers and powders, less safety precautions are necessary. Overall, WAAM is particularly suitable for the production of large components in the aerospace, construction and shipbuilding industries as well as in the oil and gas industry.

Full service for the highest demands

Ugitech offers its customers comprehensive technical support. Experts worldwide assist in the selection of corrosion-resistant, high-performance stainless steels with the desired mechanical and structural properties. The special steel manufacturer uses the latest control and testing technologies. The raw material for the UGIWAM® wires is produced in Ugine (France) which laboratory is ISO 17025 accredited. Customers therefore benefit from extensive process control and receive products of the highest quality – which are also precisely tailored to their needs.

Ugitech will showcase its latest additive manufacturing products at the 3D Print Congress & Exhibition (7th edition), which has been postponed due to the coronavirus pandemic and is now scheduled to take place in Lyon from 5 to 7 April 2022.