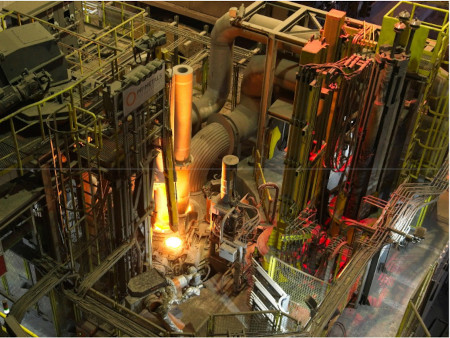

Head Hardening System for Arcelormittal Poland

Leading European high-speed rail producer ArcelorMittal selected Danieli technology for its research and development project focusing on the manufacturing of premium quality rails in Dąbrowa Górnicza, Poland.

The investment will make it possible to deliver 120-m-long head-hardened rails according to the latest European and American standards, in an efficient and environmentally friendly way.