Primetals Technologies to revamp continuous pickling line of hot rolled strip for Tokyo Steel

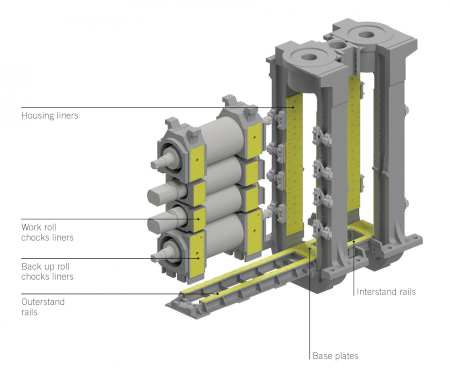

In late March, Japanese steel producer Tokyo Steel Co., Ltd. (Tokyo Steel) placed an order with Primetals Technologies to revamp a continuous pickling line of hot rolled strip at the company ́s production plant in Kurashiki City, Okayama Prefecture, Japan. The project includes the addition of a tension leveler type scale breaker and the installation of an iBox pickling tank with acid concentration control. The revamp will increase productivity for difficult-to-descale materials while reducing energy and acid consumption. The modernization project is expected to be finished in October 2021.