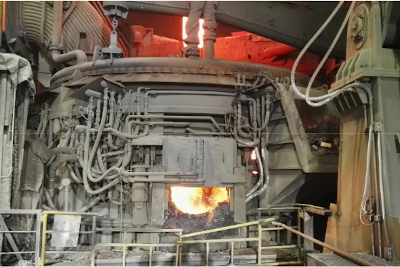

Primetals Technologies supplies new Arvedi ESP line to steel producer in Chinese Hebei Province

A Chinese steel producer located in Hebei Province has placed an order with Primetals Technologies for the supply of an Arvedi ESP (Endless Strip Production) line. The casting-rolling facility will be part of a new steelmaking facility with one BOF currently under construction.