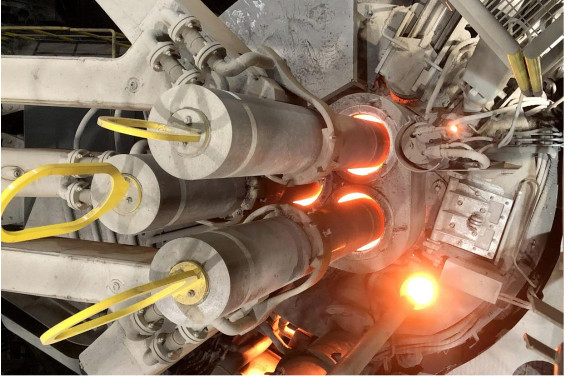

SMS group installs its first AI-based Integrated Operating Center at Daye Special Steel

- Centralized operator monitoring of the entire 460 millimeter tube plant using AI video analytics

- Only six operators are required to supervise the entire rolling line

SMS group has completed its first X-Pact® IOC (Integrated Operating Center), a central monitoring room for the entire 460-millimeter tube plant, at Daye Special Steel in Hubei Province, China. With the Daye 460 project, which also includes the enhancement of the tube plant's existing automation systems, SMS group has achieved a breakthrough in its Integrated Operating Center (IOC) application, an important milestone on the path to X-Pact® Lights-out.