Alleima and Tenaris to supply Petrobras with corrosion resistant alloy OCTG tubing for offshore Brazil

As part of the strategic alliance with Tenaris, Alleima will be the supplier of Oil Country Tubular Goods (OCTG) tubes with Corrosion Resistant Alloys (CRA) material in a new long-term frame agreement between Tenaris and Petrobras. The agreement includes the three-year supply for offshore Brazil, where pipes will be used in the customer’s various exploration and production (E&P) wells in the pre-salt fields.

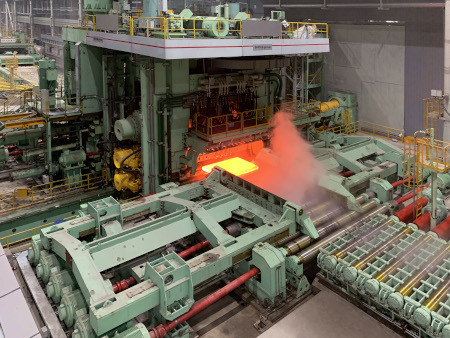

The frame agreement entails the provision of pipes produced by Alleima with CRA materials and finished with TenarisHydril Blue® premium connections and Dopeless® technology. The products will be manufactured by Alleima in Sandviken, Sweden, and threaded at Tenaris’s threading facility in Aberdeen, Scotland. The frame agreement for the three-year supply of plain end tubes from Alleima has an estimated value of up to SEK 1.3 billion, with the first order expected during first half of 2023.

Alleima and Tenaris have a strategic partnership since 2003, to add value to the oil and gas industry through joint research, product development, and the manufacture of specialized tubular solutions for demanding applications.

“We are delighted to have been awarded this contract and to secure a long-term supply arrangement towards Petrobras, through our partnership with Tenaris. Our OCTG tubes fit perfectly for this project, with its high mechanical strength and excellent corrosion resistance”, says Nigel Haworth, President of business unit Energy.

“This contract confirms our ability to supply a full range of tubular solutions for our customers operating in the most complex environments. Through strategic alliances such as the one with Alleima, along with our Rig Direct® service model and the unmatched capacity of our global supply chain, Tenaris has become the most comprehensive supplier of solutions for complex offshore operations, not only in Brazil, but worldwide,” says Renato Catallini, Tenaris President in Brazil.