New Scan System with 20-Millimeter Aperture Broadens Product Portfolio

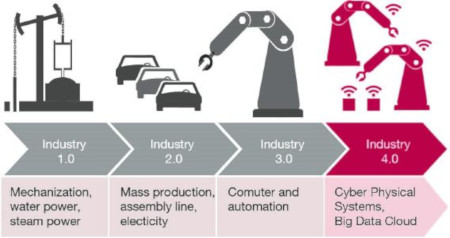

Laser technology manufacturer SCANLAB GmbH is extending its premium-segment product family with the excelliSCAN 20. This new scan system targets exceptionally demanding applications such as micromachining and additive manufacturing (3D printing).