voestalpine BÖHLER Edelstahl, a subsidiary of the international technology and capital goods group voestalpine and located in Kapfenberg, Austria, has placed an order with SMS group www.sms-group.com to supply an electric arc furnace, an AOD converter and secondary metallurgical facilities for the construction of a high-tech stainless steel plant which will set new standards in energy efficiency, environment protection as well as innovative automation of the production processes.

The new stainless steel plant is intended to replace the existing plant of voestalpine BÖHLER Edelstahl GmbH & Co KG at the Kapfenberg location and will produce 205,000 tons of high-performance steels per year for application in the aerospace and automotive industries as well as for the oil and gas sector.

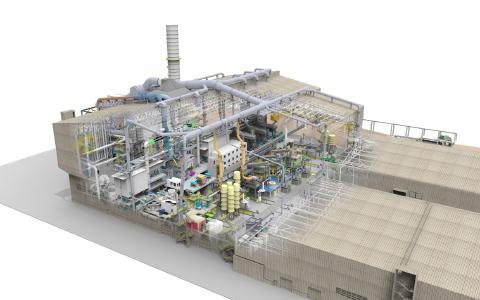

On a site of approximately 50,000 square meters, the globally most advanced plant for the production of stainless steel will be established within the next three years. Hot commissioning is scheduled to take place in the middle of 2021.

The steel plant concept unites cost-efficient process solutions with optimized process sequences and high plant availability. The plant engineering will feature a high degree of automation and digitalization in all production steps.

The centerpiece of the plant will be a 55-ton electric arc furnace (EAF) able to melt high-purity scrap and alloys into liquid steel on the basis of electrical power that is completely generated by renewable energy sources. In addition, the exhaust heat generated during the process will be used to dry the ultra-pure scrap in a separate plant before it is fed to the electric arc furnace.

The 60-ton vacuum converter will combine the classical AOD process for medium carbon contents with decarburization and degassing under vacuum for steel grades having low and ultra-low contents of carbon and nitrogen.

The scope of supply furthermore includes three ladle furnaces (LF), two vacuum degassers (VD), one vacuum oxygen degasser (VOD) and one ladle treatment stand (LTS). The VOD system will be used for the production of special high-quality stainless steel grades of highest purity.

In terms of energy efficiency and environment protection, too, the new stainless steel plant will set new benchmarks. Closed cooling water circuits and heat recovery systems will minimize emissions and the consumption of resources. Forward-looking air purification systems will meet the most stringent environmental requirements.

All components of the stainless steel plant will be equipped with

X-Pact® electrical and automation systems. The X-Pact® MES 4.0 production planning system and the innovative X-Pact® process guidance system (PGS) will lay the foundation for digitalization of the most-advanced stainless steel plant worldwide.

The manufacturing execution system X-Pact® MES 4.0 is the holistic, modular solution for planning and control of the entire metallurgical process chain and of all production facilities. Based on planning modules, it considers the interaction of all factors relevant for decision, such as plant condition, product quality and energy consumption, i.e. horizontal networking takes place. Reporting is completely web-based and provides detailed data analyses.

For all facilities within the plant, the automation concept X-Pact® process guidance will merge process-oriented operation of the different automation levels in a uniform look and feel. The modular design will provide a basis for reporting, tracking, material management and for metallurgical models. New sensors can be added respectively available data be transferred shortly.

All components of the stainless steel plant will be monitored in a central control station.

SMS group will furthermore supply the technological equipment for the Kapfenberg training center where the complete plant complex will be digitally visualized for training purposes.

The supply scope of SMS group includes basic and detail engineering, mechatronic plant technology, supervision of erection on site and commissioning of the above mentioned components. To make sure transition of production from the existing to the new stainless steel plant will be accomplished smoothly, it is planned to train the customer’s staff on site and in the test center of SMS group in Germany.