The ArcelorMittal production plants in Belgium are part of the ArcelorMittal Group, which manufactures high-grade steel products for a wide range of industries. In its Gent factory, the time had come to exchange the existing converters, and Siemens was commissioned to carry out the retrofit. The modernization was integrated effortlessly into the existing infrastructure, and enabled ArcelorMittal to radically improve its plant availability. Siemens supplied the components precisely on schedule despite an extremely tight timeframe, allowing production to carry on without disruption.

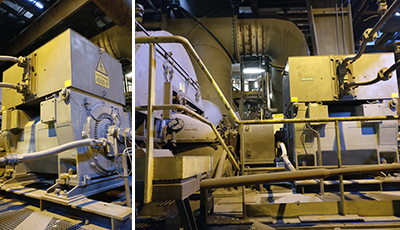

In the Gent plant, the drives included three Simovert MV converters as part of a redundant system. As the availability of spare parts for the converters dating back to 2006 was already severely compromised, it was becoming more of an issue for ArcelorMittal to obtain necessary spares in the event of a fault. This prompted the company to opt for a retrofit. It was important for the new components to permit integration into the existing water cooling system. A decision was taken to replace one of the old converters with a new Sinamics GM150.

Secure spare parts supply and plant availability

By installing the new converter, it is now possible for the company to cannibalize the decommissioned model for spare parts to supply the remaining two Simovert MV converters. This has provided a stock of spares and ensured plant availability for the foreseeable future. Trouble-free integration of the new converter into the existing drive has meant a rapid return on investment, as the existing motors can still be used.