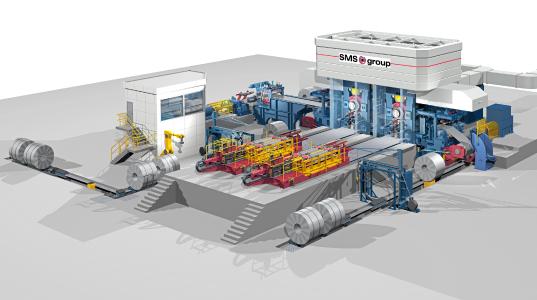

Marcegaglia Ravenna S.p.A. has contracted SMS group for the complete supply of a two-stand reversing cold mill of CCM® (Compact Cold Mill) design. Marcegaglia's head-quarters is located in Gazoldo degli Ippoliti, in the Mantua province in North Italy.

The new CCM® will be implemented at the Ravenna facility where Marcegaglia produces cold rolled carbon steel sheets and strips for a wide range of industrial applications. As a high-performance mill, it is designed to process a comprehensive material mix, including high-carbon and duplex steels, chrome-manganese alloyed steels, and silicon steels. The annual capacity is about 550,000 tons.

Depending on the product mix, it rolls strips with widths of between 750 and 1,570 millimeters and entry thicknesses ranging between 0.60 and 5.00 millimeters. The minimal achievable final thickness is 0.23 millimeters.

The CCM® will be equipped with one pay-off and two reversing reels. Both rolling stands will be realized in four-high design. It will be possi-ble to operate the mill with work roll sets of two different diameters.

Excellent strip quality, high productivity and efficient rolling operations are provided by proven SMS group rolling technologies, like e.g. the CVC®plus (Continuously Variable Crown) roll shifting technology, which, in combination with work roll bending, ensures a wide flatness setting range. One dry strip system per stand will be provided to remove surplus emulsion from the strip surface. The plant will be equipped with the X-Shape flatness measuring and control system, which, together with multizone cooling, ensures optimal flatness results of the finished strip.

The CCM® will be operated with the X-Pact® automation package, which provides a consistent and complete system solution for the high-performance control concepts and strategies implemented by SMS group.

In addition to the features aimed at optimizing plant efficiency, the TRC® (Total Roll Gap Control) assistance system developed by SMS group is going to be applied for automatic and stabilized strip threading into the pre-set optimized roll gap. The assistance system makes for stable rolling right from the strip head end, increasing the material yield as a result of reduced strip bulging at the head and tail ends.

The very high automation level of the CCM® is an important step towards digitalization and adaptability to future requirements.

The new CCM® at Marcegaglia Ravenna S.p.A. is expected to start operation in April 2020.