Wuhan Iron & Steel, based in Wuhan, China, has granted SMS group the final acceptance after the successful modernization of finishing stands F4 and F7 in their High-Capacity Hot Strip Mill No. 2. The objective of the project was to increase plant availability.

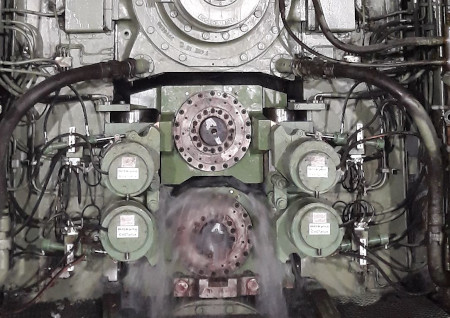

The High-Capacity Hot Strip Mill No. 2, supplied by SMS group, has been in operation at Wuhan Iron & Steel (WISCO) since 2003. In 2015, a modification by SMS group of the mill’s coiler enabled WISCO to expand its range of high-strength and pipe grade products. The recent installation of advanced work roll bending and shifting systems has provided a further boost in plant availability. The revamping of the finishing stands F4 and F7 by SMS group included the installation of CVC®plus systems with ±150 millimeters shifting stroke and the adaptation of the hydraulic valve stands. The modifications could be performed as planned during the regular 2019 annual shutdown of the mill because just little machining of the mill housings and only very few adaptations of the machine piping were required.

Through specifically tailored, well-conceived revamps, SMS group can boost the performance of hot wide strip mills and match growing market requirements.

The robust and future-oriented design of plant and equipment supplied by SMS group makes mill operators benefit from high and growing added value over many decades.