Benxi Iron & Steel grants final acceptance for hot-strip mill modernization, confirming its trust in modernization expertise from SMS group

Benxi Iron & Steel (Benxi), China, has issued the Final Acceptance Certificate to SMS group for the successful modernization of their 1,700-millimeter No. 1 hot-strip mill.

The objective of this project was to bring the mill’s production capacity and the production range – by adding high-strength steels – up to the requirements of the hot-strip market. Continuing their longstanding cooperation with SMS, Benxi again banked on the know-how, expertise and leading technology from SMS group for the project – meanwhile the fifth comprehensive modernization of the mill, which was first commissioned in 1987.

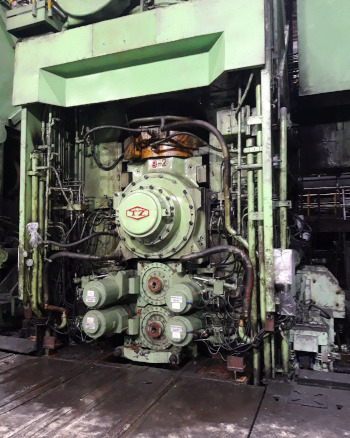

As a key part of the modernization, three CVC®plus (Continuously Variable Crown) work-roll bending and shifting systems have been installed in the finishing stands F2 to F4, complete with the associated valve technology. These systems enhance the geometrical tolerances of the hot strip.

The optimization measures performed on the rolling stands F2 to F4 comprised not only the mill stands themselves but also the interstand areas. Improved guides and new work-roll cooling systems have been installed on the entry sides of all three stands. The innovative roll gap lubrication system, in combination with the optimized roll-gap cooling system, reduces the mechanical stresses (forces and torques) acting on the rolling stands, prolonging the roll lives as a result. Thanks to the resulting boost in performance capacity of the finishing stands F2 to F4, the mill can now also produce strip in high-strength grades.

Further, the back-up roll balancing systems in the finishing stands F1 to F7 have been upgraded by replacing the emulsion-based balancing hydraulics with oil hydraulics. This measure involved the replacement of the cylinders and the complete control system, including the connecting pipes and the piping within the stands. In addition, in stands F1 and F5 to F7, the work-roll locking systems on the operator side have been replaced by a reinforced design.

Benxi benefits from the modernization in terms of enhanced mill availability, higher product quality and a more stable finish-rolling process.

“Based on the very good cooperation with SMS group in the past and their innovative solutions, we entrusted SMS group also with this recent mill revamp. With SMS as our partner, we can be sure that our mill will always be up to date and that we can response to the growing requirements of the market in an economically efficient way,” says Song Dawei, Deputy Manager of the HSM#1 Equipment Department.