Danieli Service Center in Coraopolis, Pennsylvania, USA delivered to Nucor Steel Gallatin a fully refurbished original F2 rolling mill stand pinion gearbox, part of the six-stand hot-strip finishing mill.

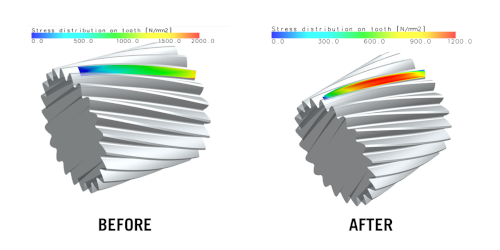

Danieli rolling mill experts reverse-engineered the original pinions for remanufacturing, which was executed at Danieli Headquarters’ specialized gear manufacturing center in Italy. The pinions were re-designed to improve teeth contact and load capacity. The new design increases the mill safety factor by 30% by implementing of different gear parameters. Additional improvement on contact pressure distribution has made it possible to decrease local contact pressure by 40% thanks to specific teeth corrections.

Gearbox body was overhauled to recover the original geometry: bearing seats has been recovered by re-machining the area and installing new bushings, which allowed perfect contact pattern. Furthermore, new double-tapered roller bearings have been installed in place of the original, spherical ones, increasing service life by approx. 10%.

After reassembly of the parts, the gearbox was run tested and vibration analysis proved the proper frequencies. Danieli Service specialists supported Nucor Steel Gallatin with accurate on-site alignment.

In the USA Danieli operates two refurbishment centers, in Coraopolis, Pennsylvania, and Ashland, Kentucky.