Green Steel from deserts silk road

- Vision without Action – No

- Vision with Action – Yes

- Green Steel worldwide – Yes

- Green Steel with fair competition in world steel market including development and transition countries – Yes

- Green Solar Power – Yes

- Green Water Power - Yes

- Green Hydrogen – Yes

- Green Iron Ore – Yes

- Green DRI – Yes

- Green Steel in competition to other materials – Yes

Content:

- What is Green Steel?

- General target of transition from „Brown Steel“ to „Green Steel“

- Global regions and actual production quantity of Steel

- Green Steel with fair competition in world steel market including development and transition countries

- Value & Production chain History from ore / coal to finished steel in NRW and Germany based on Blast Furnace and DRI

- Planning in NRW, Germany, EU and worldwide for a period up to 2035 or even 2050

- Different CO2 emissions for steel making based on different raw materials in different processes- Sustainability

- Green Sun Power, Green H2, Green Iron Ore and Green Steel from deserts along the new Silk Road in Iran with skilled engineers/workers and experiences in DRI and short distance logistics by railway to China and EU

- Public Subsidies for R&D for Green Energy and Green Steel in NRW, Germany and EU

- Public Subsidies for Investment and Operation of Green Energy, Green H2 and Green Steel in NRW, Germany and EU

- Fundamental Condition today and in future: Question, Answer, Solution for NRW, Germany and EU

1. What is brown steel? It is steel made by Blast Furnace Route with CO2 emission

What is Green Steel? There is no definition!

Is Steel only green if renewable energy like sun and wind power is generally used also for production of H2 and DRI? Is Steel green, if it is produced with energy from nuclear power plants generally and also for production of H2 and DRI? Is Steel green, if water power with water storages is used also to produce H2 and DRI? Is Steel green, if it is produced with natural gas as reduction agent and use of CCS- Carbon Capture Storage?

2. General target of transition from „Brown Steel“ to „Green Steel“

Worldwide production of Steel and Steelproducts free of CO2 emissions. It must be worldwide because German steel production is only 30 Mio t/year and world steel production is 2 Billion t/year, from which is 50% produced in China mainly with blast furnaces.

3. Global regions and actual production quantity of Steel

Country thousand tonnes per year:

| China | 996342 |

| India | 111351 |

| Japan | 99284 |

| United States | 87761 |

| Russia | 71897 |

| South Korea | 71412 |

| Germany | 39627 |

| Turkey | 33743 |

| Brazil | 32569 |

| Iran | 25609 |

| Italy | 23190 |

| Taiwan, China | 21954 |

| Ukraine | 20848 |

| Mexico | 18387 |

| Vietnam | 17469 |

| France | 14450 |

| Spain | 13588 |

| Canada | 12897 |

| Poland | 8956 |

| Saudi Arabia | 8191 |

| Indonesia | 7783 |

| Belgium | 7760 |

| Austria | 7424 |

| Egypt | 7257 |

| United Kingdom | 7218 |

| Malaysia | 6820 |

| Netherlands | 6657 |

| South Africa | 6152 |

| Australia | 5493 |

| Bangladesh | 5100 |

| Sweden | 4721 |

| Argentina | 4645 |

| Czechia | 4437 |

| Thailand | 4246 |

| Kazakhstan | 4134 |

| Slovakia | 3600 |

| Finland | 3473 |

| Romania | 3448 |

| United Arab Emirates | 3327 |

| Pakistan | 3304 |

| Belarus | 2621 |

| Qatar | 2558 |

| Algeria | 2400 |

| Luxembourg | 2119 |

| Portugal | 2033 |

| Oman | 2000 |

| Serbia | 1929 |

| Philippines | 1915 |

| Hungary | 1769 |

| Switzerland | 1500 |

| Greece | 1350 |

| Colombia | 1333 |

| Kuwait | 1270 |

| D.P.R. Korea | 1250 |

| Peru | 1230 |

| Chile | 1133 |

| Bosnia and Herzegovina | 801 |

| Singapore | 766 |

| Bahrain | 700 |

| New Zealand | 667 |

| Uzbekistan | 666 |

| Slovenia | 623 |

| Norway | 621 |

| Ecuador | 607 |

| Libya | 606 |

| Bulgaria | 566 |

| Morocco | 500 |

| Moldova | 392 |

| Jordan | 350 |

| Myanmar | 350 |

| Guatemala | 306 |

| Israel | 300 |

| Macedonia | 239 |

| Cuba | 230 |

| Azerbaijan | 200 |

| Others | 115 |

| El Salvador | 102 |

| Nigeria | 100 |

| Montenegro | 75 |

| Croatia | 69 |

| Uruguay | 62 |

| Venezuela | 51 |

| Tunisia | 50 |

| Sri Lanka | 30 |

| Paraguay | 26 |

| Ghana | 25 |

| Kenya | 20 |

| Syria | 5 |

4. Green Steel with fair competition in world steel market including development and transition countries

If the aim is to produce green steel worldwide, then financing from large subsidised steel producers in Germany and the EU must be given interest-free credits to steel producers in poor countries in order to achieve fair conditions and prevent them from disappearing from the market. Green Steel with Green Energy should be not „The race for subsidies“ against free world trading and WTO. It should not kill the steel producer in development and transitoion countries by unfair conditions due to lack of money for transition to Green Steel.

This is a principle of political culture, even if German politicians do not get any votes for it in the election to the German parliament.

5. Value & Production chain - History from ore / coal to finished steel in NRW, Germany and EU

Shortening of the value & production chain in past in NRW to keep price of steel from NRW competitive. Changes can be helpful to keep steel from NRW competitive and to safe workplaces. But: „Less is better than nothing“.

Examples from past:

19th and 20th century

Originally steel in Germany by Thyssen, Krupp, Röchling etc. was made from European ore (Lorraine / Sweden), German coal / Ruhr region to finished steel products for example rails, sheets etc.

1955

Willy Korf foundet Mini steelworks with DRI (Direct Reduction Iron). Quote from magazine „Der Spiegel“: "In the mid-fifties, Korf began his fight against the snooty steel managers from the Ruhr (Thyssen, Krupp) and Saar (Röchling)."

Willy Korf: At the beginning of the eighties introduction of DRI, 10,000 employees worldwide and a turnover of 2.5 billion DM (still today direct reduction in Hamburg - HSW - remaining – belonging to Arcelor Mittal).

1970

Shortening of the (value) production chain by Elimination of European coal and ore in value chain of steel production in Germany.

2010

Shortening of value chain in Germany by New Iron & Steel Plant from ThyssenKrupp Steel in Brazil - partially shortening the production chain in Germany by partially locating to Brazil – partly elimination of blast furnace (pig iron), converter steel plant (liquid steel) - continuous slab casters (solid cc blooms and slabs) in Germany. Import of CC Slabs from Brazil to Germany for hot-, cold rolling and final treatment of steel products in Germany.

2012

"ULCOS" analysis: Due to CO2 emission the blast furnace must be replaced by direct reduction.

ULCOS - Ultra Low CO Steelmaking - Published: 23 Aug 2013

“If one considers the overall process from the sub-processes iron production and steel production then applies: The iron making process in Blast Furnaces is the most emissions intensive part for making steel producing between 70 and 80 per cent of the total emissions from producing steel.” What was the answer to ULCOS in Steel Industry, Politics and society ? None!

Only when “Future for Friday” and the green majority in society reached the policy, the steel industry reacted in the “Main Stream” and is looking for „Green Steel“.

2020

According to ThyssenKrupp Stahl, the state must support ThyssenKrupp Steel in the transition from blast furnace to direct reduction.

6. Planning for a period up to 2035 or 2050

This period is so long that it is completely unrealistic from ecological- , economical – political point of view, influence of society and strategy of political parties to draw up a master plan with a cost-benefit forecast.

Therefore there is no master plan with cost analysis in the public domain up to now available.

However, there is talk of 35 billion Euros for investments in Germany for the transformation to H2 based industry including transition from the blast furnace to the DRI with H2. For what is the number of 35 Billion Euro? It’s not known to the public.

7. Different CO2 emissions in different processes for steel making based different raw materials

- From Ore to Steel

- From Scrap to Steel

- With circular economy

- Sustainability with longer life of steel products is the most efficient way to reduce the CO2 emission

Sustainability „Green Steel“ Note: the most sustainability is not 1st from ore to steel product, 2nd from scrap to steel product, 3rd circula economy with recycling but 4th longer use of steel products like automobiles by design which allows easy replacement of all wear parts and implementation of creativity and development with change of PR of automobile producer and political parties, what means less lobbyismus. No Srapping Premium or any Premium payed by government with tax money.

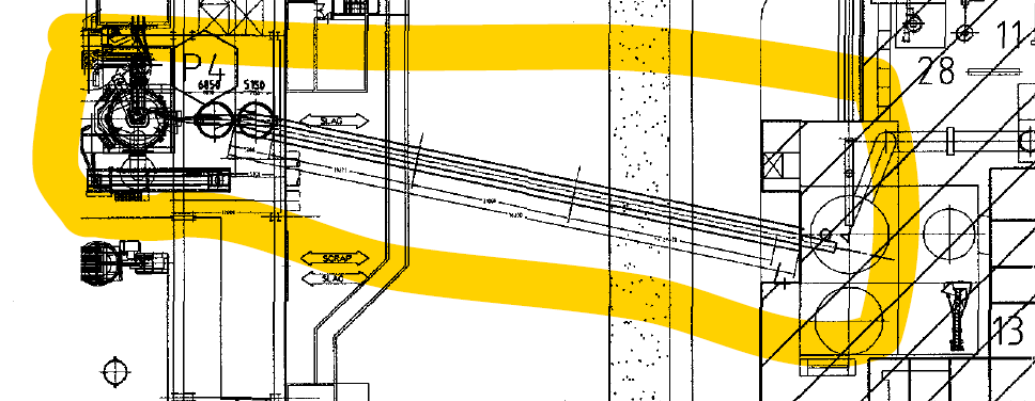

8. Green Sun Power, Green H2, Green Iron Ore and Green Steel from deserts along the new Silk Road with skilled engineers/workers and experiences in DRI and short distance logistics by railway to China and EU

China has built the new silk road connecting China with Eurasia and Africa.

The ancient Silk Road brought an advance in culture, science and commerce between all peoples on the Silk Road. The new Silk Road will also achieve this for China, Eurasia and Africa.

Example: Iran Deserts along the Silk Road can use all users with uninterrupted solar energy with salt smeelting to generate green electric energy continuously 24 h /day, to generate uninterrupted H2, to generate local iron ore, having skilled steel engineers / steel workers with DRI experiences which can generate „green steel” in the desert.

The energy is stored in CC-Slabs and CC-Blooms not in H2 and can be transported more easily than electricity or hydrogen by rail on the Silk Road. In this way steel remains economically viable and competitive compared to other materials.

Eurasia with Africa can become the largest economic area through cooperation and competition and give a signal from China’s peaceful history, in past never started a war by chinese people.

Green Steel with green Energy can be produced only by global optimization of value chain for example in deserts with continuous sun power and iron ore along railways like New Silk Road between China and Germany via deserts in Kasakhstan, Iran, Turkey, etc.

These include the great dry deserts of South America (Chile), EURASIA with the Middle East (Iran, Saudi Arabia) and Asia (Casakhstan, China) and Africa (Morocco) as well as EU countries such as Spain.

- Deserts with solar energy for green steel with uninterrupted energy by sun during the day and from the hot salt melt in night and H2 storage at night,

- Deserts with iron ore

- Deserts with DRI plants

- Deserts with logistical connection to Duisburg end of silk road on west, NRW - North Rhine-Westphalia and EU by the new Silk Road railway

9. Public Subsidies for R&D for Green Energy and Green Steel in Germany and EU

R&D is based on public and private money. This is helpful, that public institutes are involved, to avoid, that only private institutes are based on fast economical results are able, to develope new environmental protection against climate change, materials, processes and plants.Private research and development should take care also, that there is a positive result for the benefit of the private institute and company behind and to develop basis and near application R&D.

But it should be not „The race for subsidies“ especially as German Steel Producer in past has fighted against steel subsidies in China, Japan and Korea“.

If answer is yes, Public Subsidies for R&D should be for R&D in all sizes of Institutes and Companies - SME and Big- especially also for Start Ups.

If answer is no, German and EU Steel producer must look for solutions with international cooperation.

NRW - North Rhine-Westphalia 1.6 million Euros subsidies allready given.

The NRW Ministry for Economic Affairs, Innovation, Digitization and Energy announces: 1.6 million Euros funding for thyssenkrupp Steel, Air Liquide and the steel research institute BFI Minister for Economic Affairs and Energy Prof. Dr. Andreas Pinkwart presented the funding decision for a pioneering and promising climate protection project to reduce CO2 emissions in steel production to Thyssenkrupp Steel, Air Liquide and the steel research institute BFI. The state is funding the first phase of the project with 1.6 million Euros.

WM Commentary – these are all 3 representatives of the Integrated Ironworks at the Duisburg site with outstanding experts from research, development and practice. However, it is always good to bring other experts on board without conflicts of interest. The project consortium is planning the technical testing of a new, modified blast furnace process in which hydrogen (H2) is to partially take over the role of fossil carbon reduction. The addition of hydrogen is intended to displace coke or blown-in coal. The technology is regarded as a pioneering technology for a future possible climate-neutral steel production.

The H2 supply for the blast furnace is ensured by a pipeline from Air Liquide.

Minister Pinkwart: "I am particularly pleased to announce today the funding decision for the first project of the „IN4climate initiative“.

NRW, with which we are taking an important step towards a climate-neutral industry.

In order to achieve ambitious climate protection with an industry that will continue to be globally competitive in the future, industrial and energy-intensive processes such as steel production must be radically rethought. As the state of North Rhine-Westphalia, we want to follow this path of transformation together with industry and science.

The pilot project shows that our IN4climate NRW initiative is already bearing fruit. I am glad that we have thyssenkrupp Steel, Air Liquide and the BFI as innovative partners at our side.”

10. Subsidies by government of NRW, Germany and EU for investment and operation

Cannot and will not accepted by WTO, therefore it is only PR but with negative international consequences.

11. Fundamental Condition today and in future: Question, Answer, Solution for NRW, Germany and EU

Question: How effective is and will be the political, ecological, economic impact on a decarborisation of pig iron production (DRI versus blast furnace Pig Iron) with world crude steel production of 2 Billon t/ year and EU Steel Production of less than 10% and Germany with less than 2% and China with about 50% of world crude steel production?

All steel important areas like China, USA, India, South Korea, Russia has different interests but more important activities about ecology, economy oriented profit or environmental benefits or both and participation in the market.

The fight re. ecology for H2 based pig iron production has influences onto world climate change but also onto regional view onto different political, economy and social targets.

The Target of H2 reduction agent based Green Steel is worldwide absolutely possible from technology but the answer is that finished products from green steel from EU and Germany must be competitive to brown steel from rest of world and also to new materials with potential to replace steel.

Solution for NRW, Germany and EU re development/transition countries must be fair for all steel producer worldwide especially in development and transition countries which cannot finance the transition to Green Steel.

Change and shortage of value chain in Duisburg, NRW, Germany, EU and transfer of 1st - 2nd - 3rd Step in Value chain (Production Steps – from iron ore to DRI sponge iron, to steel, to CC slabs) from Iron Ore to CC Slabs into deserts with sun power and energy storage in melted salt for uninterrupted availability of Energy for electrolytical H2 Production 24 Hours/Day – 7 Days / week – 360 Days / year, continuous hydrogen production, Deserts with Iron Ore mines like Iran with existing Iton Ore Mines, benefication plants and DRI production but with H2 instead od natural gas and hot charging of sponge iron into EAF/LF and than into CC.

All this is possible in Iran with already 30 Mio t/year steel production with DRI process and plants, with high education level of engineers and workers and steel production.