- Largest-ever heat size at a vacuum oxygen decarburization (VOD) plant

- Same plant reached record-low carbon levels

- Deep know-how in steelmaking key for handling heat size this big

Recently, a vacuum oxygen decarburization (VOD) plant supplied by Primetals Technologies achieved a heat size of 298.2 tons – a world record in stainless steelmaking. In addition, the same plant reached a carbon content of 5 parts per million (ppm) after decarburization, which marks another world record for VOD plants. Turkish steel producer Çolakoğlu operates the plant, located in Dilovası about 60 kilometers to the south-east of Istanbul.

“A pioneer in the Turkish steel industry, Çolakoğlu has the courage to try new things. Our achievement at the VOD plant is the latest proof of this determination. While giving credit to my colleagues who have carried the flag and achieved extraordinary results, I send special thanks to Primetals Technologies for good collaboration and support. Together we create value by recycling stainless scrap, thus creating stainless steel for the Turkish industry – and we will contribute to reducing Turkey’s trade deficit by replacing imports,” says Uğur Dalbeler, CEO of Çolakoğlu.

Leading expertise in stainless steelmaking

To reach record-breaking results like the ones at the VOD plant, there are many obstacles in the steelmaking process that need to be overcome. For example, the process parameters for the furnace must be very accurate and well-thought-out to allow tapping at high temperatures. In that way, any clogging issues during tapping, water-cooled panel leakage, and furnace refractory problems are avoided. Also, the VOD-system needs to be designed for a very large heat size – usually, these plants operate with heat sizes between 60 to 150 tons of stainless steel.

Extra-low carbon stainless steel grades

The VOD-system is a tank degassing unit which, compared to a VD-plant, is additionally equipped with an oxygen blowing lance, vacuum pump regulation for oxygen blowing conditions, and other necessary components such as gas cooling, dust filtering, and CO-burning systems. Furthermore, advanced process models are required to reach accurate end process parameters such as end chemical analysis and liquid steel temperature. The additional oxygen supply can be used for producing extra-low carbon stainless steel grades (forced decarburization) or for chemical heating of the melt in conjunction with aluminum/silicon additions (the VD-OB process).

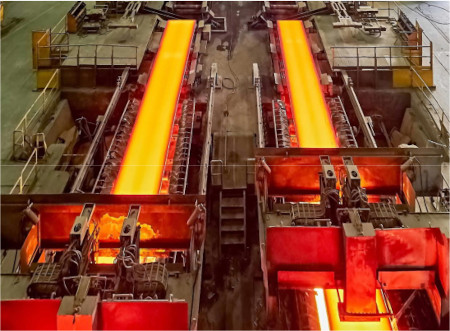

One of the world’s largest plants

Çolakoğlu operates an electric steel plant in Dilovası, located in the western part of Turkey. The main products at this plant are slabs, which are further processed in a hot-rolling mill, and billets used for producing reinforcing steel bars and steel rock bolt. The Çolakoğlu electric steelmaking plant, one of the largest in the world, was supplied by Primetals Technologies and has been in operation for several years. In late 2020, the plant was modernized and upgraded to becoming a VOD plant. This marked another step in the strong business partnership between Çolakoğlu and Primetals Technologies.