- Will add more capacity to the overall plant output

- New equipment to be installed with only minor modifications needed at the steel plant

- Startup scheduled for July 2023

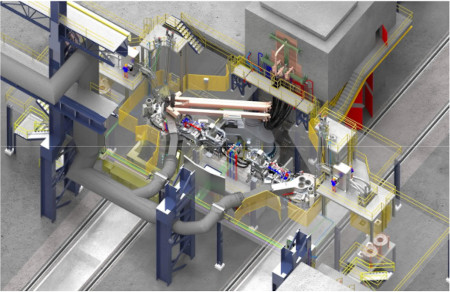

Mexican steel producer Talleres y Aceros S.A. de C.V. (TYASA) has signed a contract with Primetals Technologies for a new twin ladle furnace. The new equipment will be implemented at TYASA’s Ixtaczoquitlán site, located in the south-eastern part of Mexico. A few years ago, TYASA added a CASTRIP plant for producing coils at the plant in Ixtaczoquitlán. This resulted in a need for additional capacity at the secondary-metallurgy stage in the meltshop. Adding a new twin ladle furnace will resolve this issue and increase performance at the steel plant.

Minimized shutdown time

Installation of the 100-ton twin ladle furnace will be executed with just minor impact on production. The shutdown time is kept to a minimum, as the integration of the twin ladle furnace into the existing dedusting and water treatment systems will be possible with no more than small modifications. Primetals Technologies has created a tailormade solution for this twin ladle furnace. It is specifically designed for a future installation of a twin vacuum degasser, which will be operated in direct vicinity on the same rail tracks and with the same cars. Also, the limited space requirements in the meltshop called for a unique design.

Improved safety for operators

As part of this order, Primetals Technologies will supply automatic stirring gas couplings for the whole steel plant in Ixtaczoquitlán. The new equipment will replace the current manual process in which operators establish the stirring gas connection by hand. This addition will therefore improve the safety levels at TYASA’s meltshop. Automatic couplings will be supplied for the existing tapping car, the ladle cars of the new and existing twin ladle furnace, the vacuum degassing plant, and the counterparts at the existing ladles.

Primetals Technologies will also supply full Level 1 and 2 automation systems as well as an m.connect license so that the twin ladle furnace can be integrated with the existing m.connect system at the plant.

A long history of collaboration

A family-owned company, TYASA has about 1,400 employees and produces special steels, flat steels, coated steels, and steels for the construction industry. Primetals Technologies has a long history of successful projects with TYASA. With the aim to enter the flat product market the Mexican steel producer set up an additional production route in 2014. In the years since, Primetals Technologies has supplied a complete mini mill – consisting of a Quantum electric arc furnace, a twin ladle furnace, a twin vacuum degasser, and a continuous casting machine – and a reversing cold rolling mill.

TYASA has also ordered a CASTRIP production line from a consortium that included Primetals Technologies. To process strip from the CASTRIP line, the Mexican steel producer awarded Primetals Technologies with a contract to supply a combined galvanizing and color coating line in 2018.