A new spooler line for the production of rebars and rounds in coils weighing up to 5-tons has just been started up at the Nucor Steel Sedalia minimill, Missouri, USA.

High efficiency and highest material yield during downstream processing due to ECR endless casting rolling process allows the lowest production costs.

High mechanical characteristics and good weldability of the finished product, plus optimized coil handling, complete the benefits of the new line, which will be managed by Danieli Automation Q-VID system and deliver twist-free compact and regularly shaped coils at up to 30 m/s.

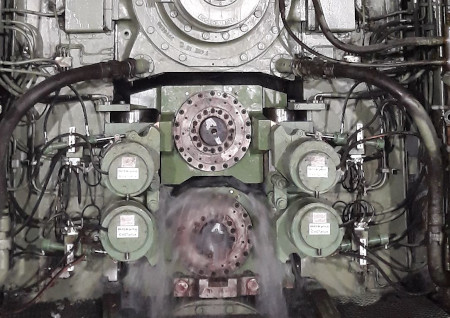

The spooler line consists of a 4-pass Delta-type fast finishing block (which will extend the Nucor Steel Sedalia product range to rebar #3); five water-boxes for heat treatment; cropping and high-speed shears; two 5-ton horizontal spooler machines; and a coil handling, strapping and collecting area.

The equipment was strategically installed in parallel with the start-up of the MIDA ECR minimills in order to minimize plant downtime needed for its commissioning.

This is the third spooler line installed and started-up downstream of a Danieli MI.DA® Micromill, and first in operation at Nucor Corporation, allowing the expansion of its current production range. A second spooler line for Nucor Group is currently under erection at Nucor Steel Florida and is planned to be commissioned by the end of this year. By that time the Danieli spooler lines installed in North America will be five.